- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

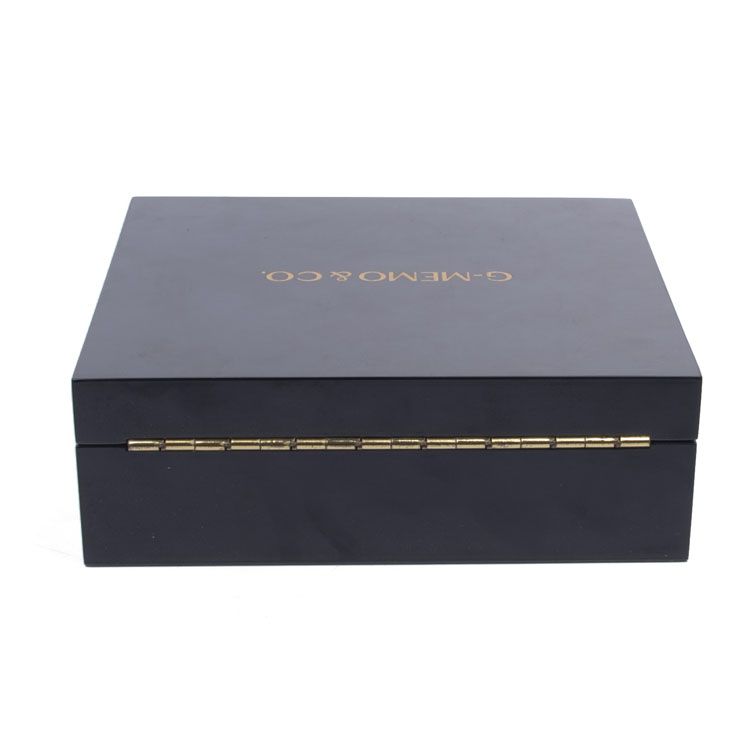

McPerfumeBox013

mcpackaging

| Availability: | |

|---|---|

BLACK SQUARE FLIP-TOP IRON-BONED PIANO LACQUER PERFUME WOODEN BOX PRODUCTION PROCESS DESCRIPTION

1. Material selection

The manufacture of black square flip-top iron-boned piano lacquer perfume wooden box requires the use of high-quality wood, such as oak, walnut or medium-density fiberboard (MDF), to ensure that the box structure is stable, durable and beautiful. The wood needs to be dried to prevent cracking and deformation. For the flip-top design, high-strength hinges and magnetic fasteners are used to ensure smooth opening and closing.

2. Wood processing

Cutting and shaping: According to the design drawings, use CNC precision cutting machines or hand-carving equipment to cut the wood into standard-sized panels, side panels and bottom panels, and polish them to ensure smooth edges and corners.

Splicing and assembly: Use mortise and tenon structure or strong glue bonding technology for splicing, and fix it with a nail gun or pressing device to ensure that the box is stable and durable. After the splicing is completed, preliminary polishing is required to remove excess glue and sawdust.

3. Piano lacquer coating

Primer treatment: Apply high-quality closed primer evenly on the surface of the wooden box to fill the wood grain and prevent uneven absorption of the paint. After the primer is dry, use fine sandpaper to polish it to make the surface smooth.

Multi-layer coating: Use high-brightness piano lacquer and spray it multiple times. Fine grinding is required after each spraying to ensure the smoothness of the paint surface. Generally, 3-5 sprayings are required to form a smooth, mirror-like effect.

Polishing and waxing: The last step is fine polishing and applying protective wax to increase the surface hardness and glossiness, making it more textured.

4. Hardware and flap installation

Flap structure: Use high-quality hinges, magnetic fasteners or spring structures to ensure that the flap opens and closes smoothly and is not easily damaged.

Hardware installation: Accurately position and fix hardware such as hinges, magnetic fasteners and decorative metal plates to ensure that they are beautiful and firm.

5. Inner support production and installation

Material selection: The movable inner support is generally made of flocked EVA, leather-wrapped plastic or high-density sponge to provide good cushioning protection.

Processing and molding: Cut according to the size of the perfume bottle, and make the lining through hot pressing or manual coating process to ensure accurate size and delicate touch.

Installation and fixation: Embed the prepared inner support into the wooden box to ensure that it is stable and can be taken out freely to replace or adjust the internal structure.

6. Finished product inspection and packaging

Quality inspection: Check whether the box is stable, whether the flap is smooth, whether the paint surface is smooth and flawless, whether the hardware is firm, and perform durability tests.

Cleaning and packaging: After wiping the finished product with a soft cloth, put it in a dust bag or foam protective layer, and finally put it in a high-end outer packaging box to ensure that there is no damage during transportation.

Through strict process and exquisite production technology, this perfume wooden box not only has high-end texture, but also has both practicality and beauty, perfectly showing the unique charm of the brand. "